TDV Grain Gravity Separator

Introduction and application:

It separates two products of same size but different specific gravity by the floating principle.

The unit selects cereals, broken grains, durum wheat semolina, maize and wheat germ, seeds, oil-seeds, coffee beans, peas, beans, nuts, and can be simoultaneously employed as a stoner.

Working principle and features:

The unit selects cereals, broken grains, durum wheat semolina, maize and wheat germ, seeds, oil-seeds, coffee beans, peas, beans, nuts, and can be simoultaneously employed as a stoner.

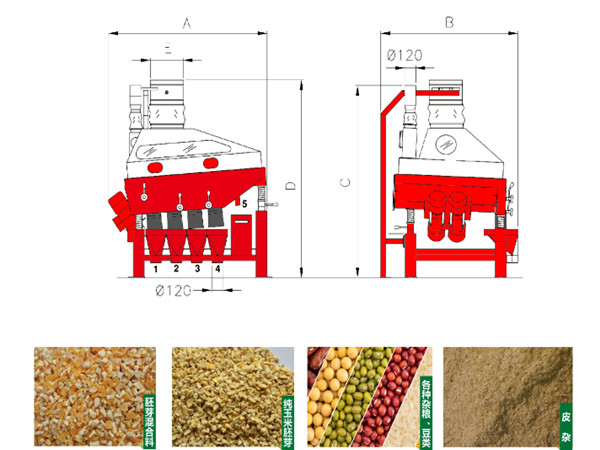

Totally enclosed, vacuum operated machine consisting of a supporting frame, an oscillating deck, an exhaust hood and a feed control device.

The selected products are conveyed to an outlet having four fixed outlets and three diverting valves for products division.

Oscillating frame with aluminium working deck covered with easily removable wire mesh or stainless steel screen.

Constant loading is ensured by the feed group provided with a spring loaded valve for air- tight operation. Large polycarbonate windows allow visual control of working deck.

The technological setting up can be performed with machine in operation by means of devices adjusting the longitudinal and cross angle.

Technical advantages:

Optional – Autoregulation system

The “load control” system provides a continuous flow meter placed at the exit of the selected product and a control unit equipped with the touch panel.

Operation is simple and intuitive: once properly adjusted the gravity separator and stored the reference value, the PLC activates a control loop via an inverter that feeds the vibromotors.

This system automatically handles the adjustment of the machine so that variations in flow or density does not affect the optimal and constant quality of the selected products.

Technical Parameters:

|

Model |

Capacity(t/h) |

Power(kw) |

Air Volum (m³/h) |

|||

|

corn |

cereals |

motor |

low pressure air |

voltage |

||

|

TDV-200 |

2.5-3 |

4-6 |

0.75*2 |

4 |

10W/220V |

8000-11000 |

120ton Pulses Cleaning and Grading Line in Uganda: A Success Story

WinTone Machinery designed a bespoke 120-ton pulses cleaning and grading line and adopt cleaning technologies, such as a

Win Tone Machinery Helps Ethiopia Establish 120-Ton Coffee Bean Cleaning Production Line

Win Tone Machinery has recently helped Ethiopia establish a state-of-the-art 120-ton coffee bean cleaning production lin

20tph Pea Cleaning and Peeling Project Installed

This 20t/h pea cleaning and peeling plant is designed by China Win Tone Machinery. This pea cleaning and peeling plant